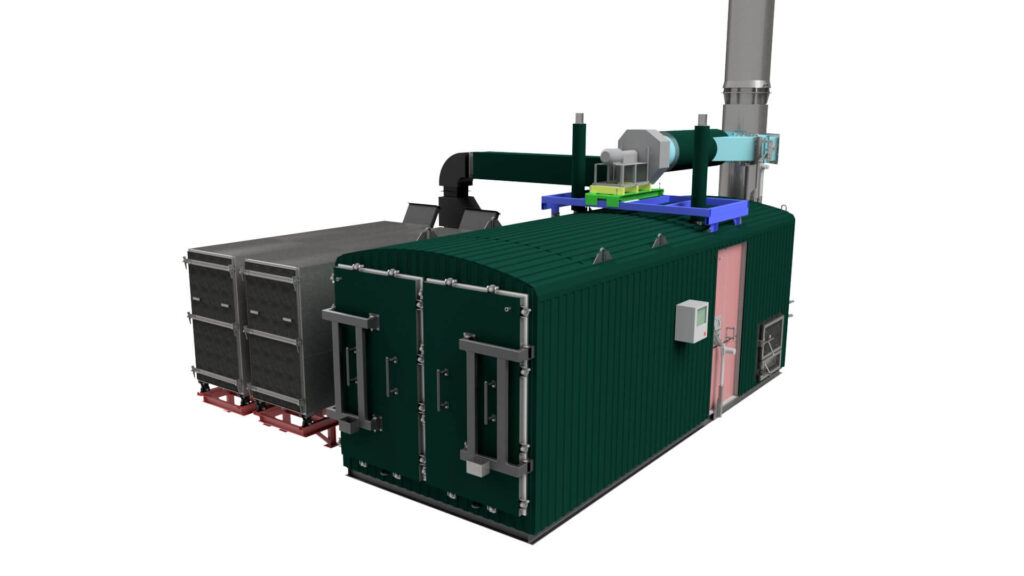

Preliminary dryer for EKKO

Pre-drying (PD) is a device for automatic preparation of a heat carrier – a drying agent for use in drying devices. The basis of the coolant is the excess heat released during the pyrolysis process

Description

Preliminary dryer is used to “quickly and efficiently” remove moisture from wood to obtain dry raw materials for pyrolysis. Preliminary drying takes place outside of the drying/pyrolysis chamber, which can significantly shorten the cycle time and increase the productivity of the kiln from 50 to 100% when using “fresh” wood.

Preliminary drying of raw materials not only reduces the duration of the process, but also affects the quality and yield of charcoal. It is recommended to apply preliminary drying, if the moisture content of raw material exceeds 30%.

Main advantages

- Increase kiln productivity

- Increase % charcoal yield

- Effective drying of “raw materials”

- Compactness

- Easy operation

- Low cost

- Security

From the table below, you can clearly see the difference in the cycle time at different humidity of the raw material for the production of charcoal.

| Relative humidity of wood, % | Cycle time, hr. |

| < 20 | > 12 |

| < 40 | > 16 |

| < 55 | > 24 |

| < 70 | > 36 |

Technical description

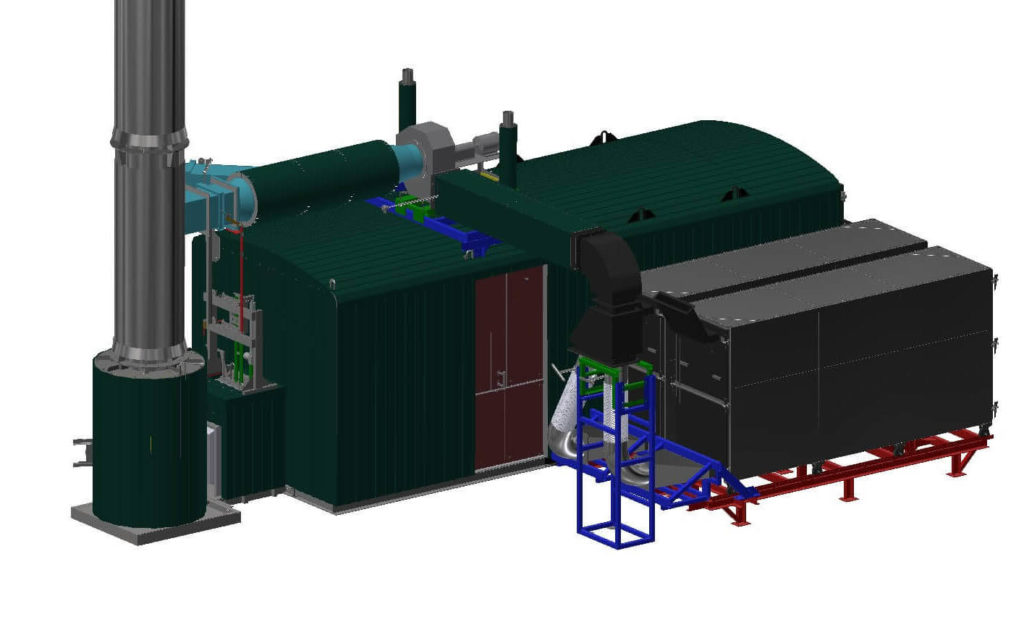

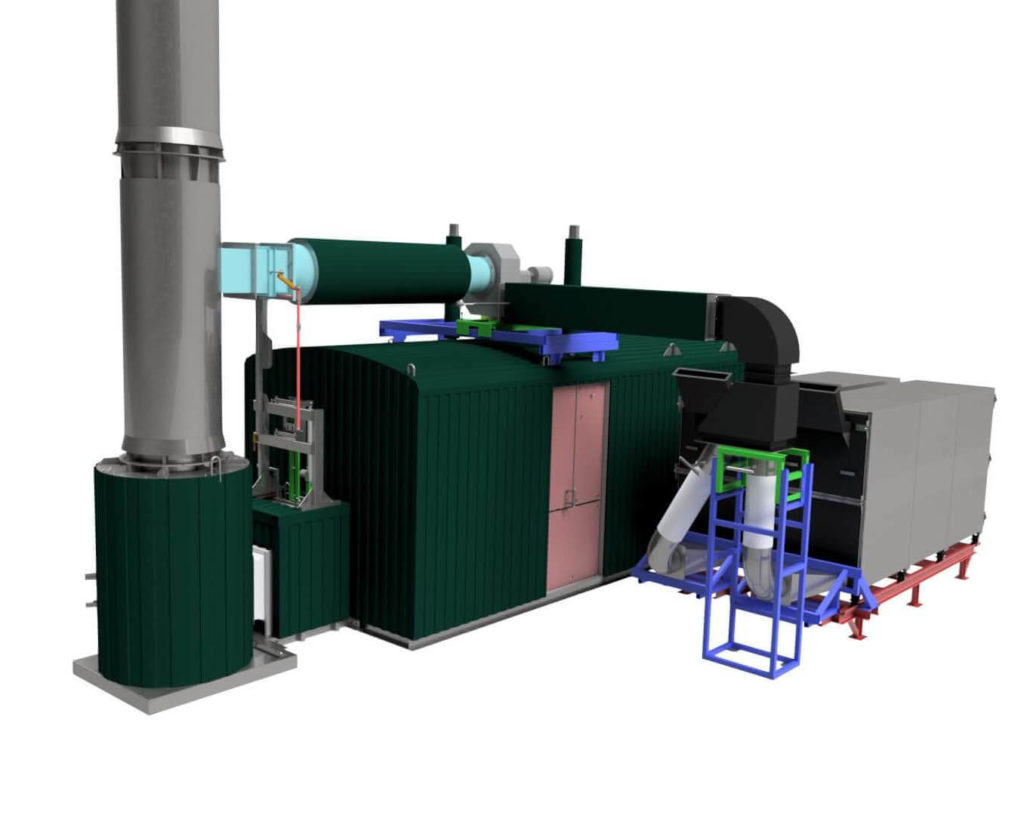

Excess heat generated as a result of carbonization of plant material enters the flue, using a high-temperature smoke exhauster (1). The hot gas is fed to the mixer (3), where its temperature is lowered to that required by mixing with cold air. The prepared heat transfer medium is then supplied through the distribution manifold (4) to the drying device (5), in this instance a EKKO trolleys.

When using the preliminary dryer, it is recommended to double the number of trolleys for one carbonization furnace. For example, if for carbonization furnace EKKO-2 min. 4 trolleys, with preliminary drying system min. 8 pcs. It is also recommended to “close” the trolley from the cold weather and hard wind, or use the drying chamber with good heat isolation.

INTERESTED IN PURCHASING?