EKKO 2 Carbonization Furnace

An environmentally friendly furnace for carbonization of raw materials, to produce high-grade charcoal. The main process used in the furnace is carbonization or low speed pyrolysis of plant materials containing carbon. In addition to the production of charcoal, heat energy is generated in the process. Extra heat can be used for preliminary drying of the raw material or for other purposes.

Based on more 20 years of experience, a unique safe pyrolysis unit has been developed, taking into account the basic requirements of modern consumers:

- Manufactured using modern insulating materials that can withstand ultra-high temperatures (up to 1300 ° C), speeding up the process and increasing plant efficiency.

- Automated control systems

- Online control & cloud storage

- Efficient design negating the need for forklifts, hoists, cranes etc

- High quality at a highly reasonable price;

- Compactness and low weight (savings on delivery);

- Economical, no additional fuel is required, only to start the furnace;

- Low consumption of electrical energy < 0,1-0,2 kWh;

- Quick start of the furnace to the operating mode < 1 hour;

- Resistance of the combustion device to thermal shock;

- Quick first start of the new furnace, preparation < 8 hours;

- Possibility of transporting two to three ovens in a container/truck;

- Charcoal retains the shape of the raw material, the fines fraction (undersize particle) of charcoal does not exceed 1%;

- High performance of the furnace, with relatively small dimensions

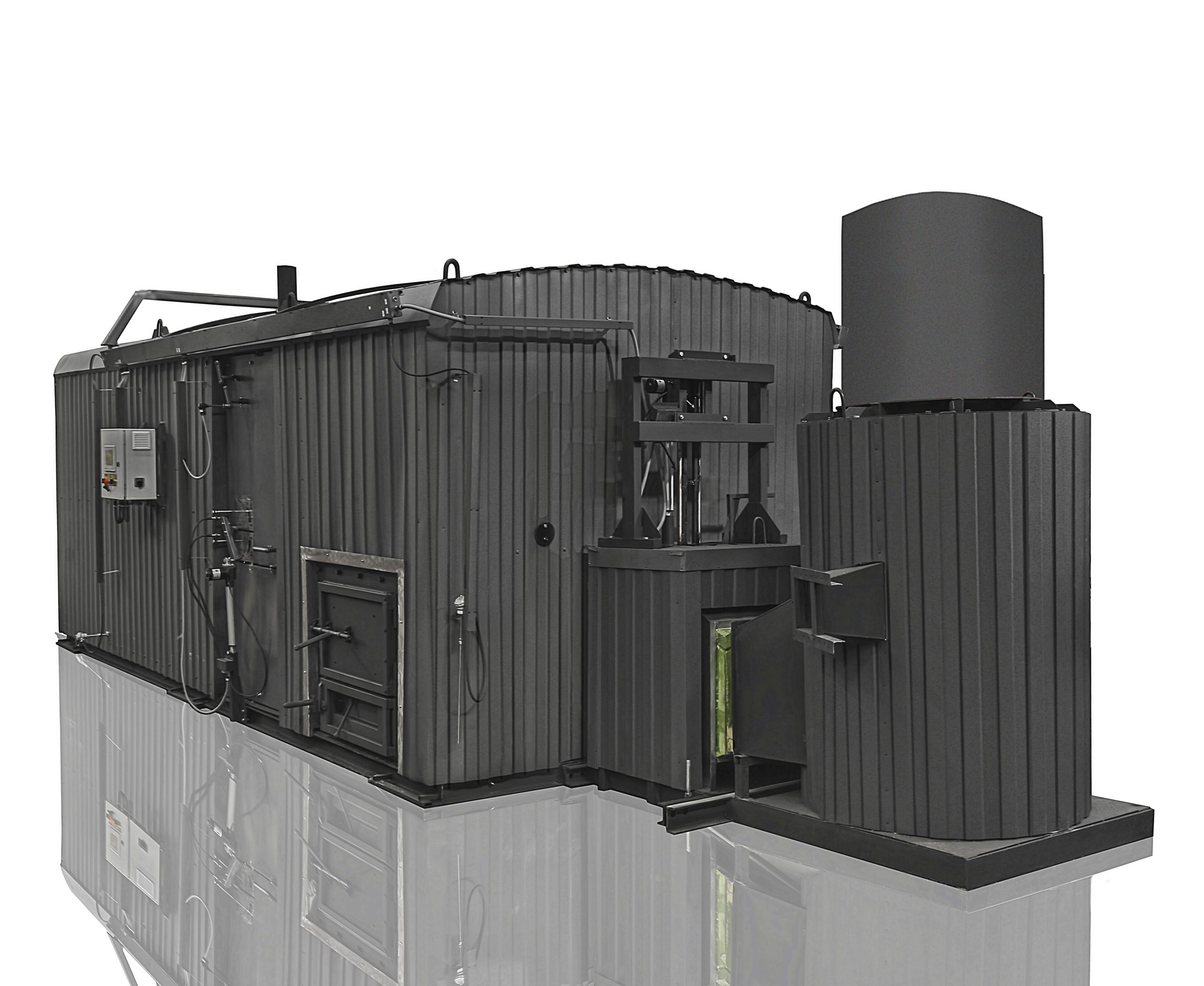

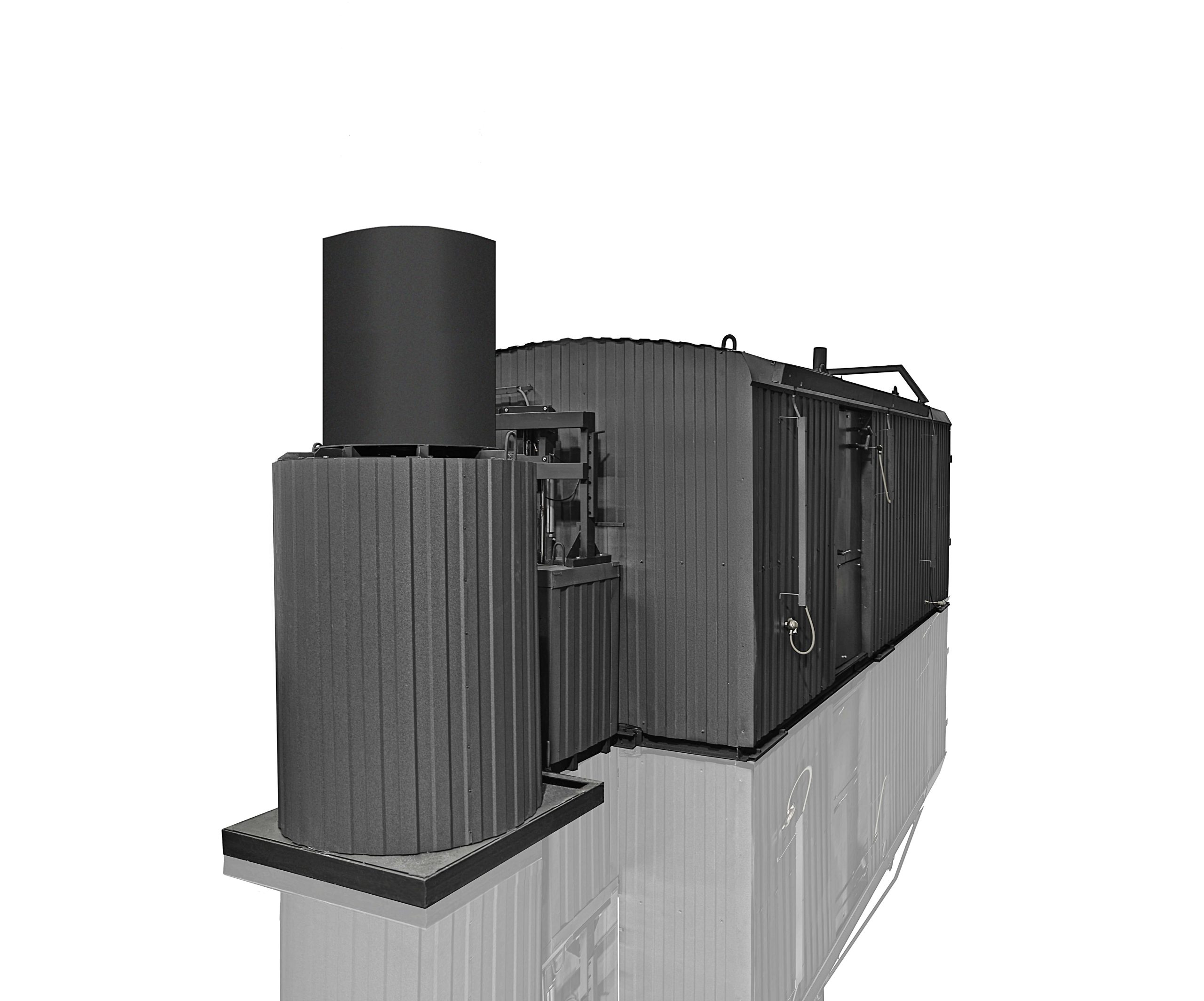

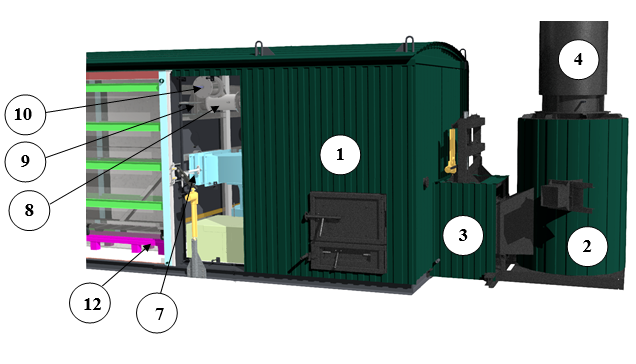

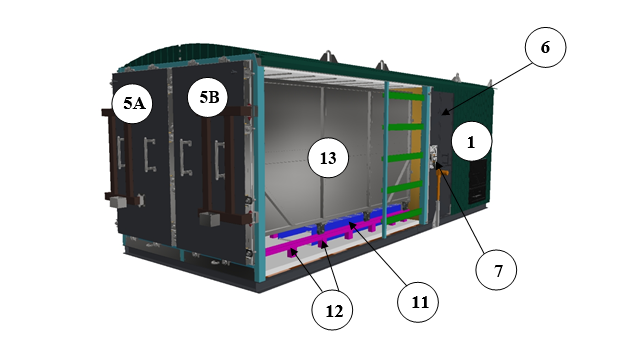

Description of the furnace

The construction of the carbonization furnace consists of two or four process chambers, which are connected with: fire-chamber; operating chamber; afterburner for eco friendly process; chimney

Process chambers operate in “DRYING” or “PYROLYSIS” modes: a “RELOADING” mode is also provided. The automatic control system(ACS) determines the mode in the chamber “DRYING” / “PYROLYSIS” / “PYROLYSIS END” / “CHARCOAL READY“. In addition, the ACS distributes the heat formed as a result of the combustion of pyrolysis gas released during the active phase of the PYROLYSIS process into other chambers that are in the passive phase of the process (DRYING or calcining of coal), this provides safety at all stages of the process. The automatic control system manages and monitors all the actions of the furnace, it also fixes all parameters, keeps logs of “temperatures and events”, personnel actions, etc. This makes it possible to comprehensively analyze and control equipment operation

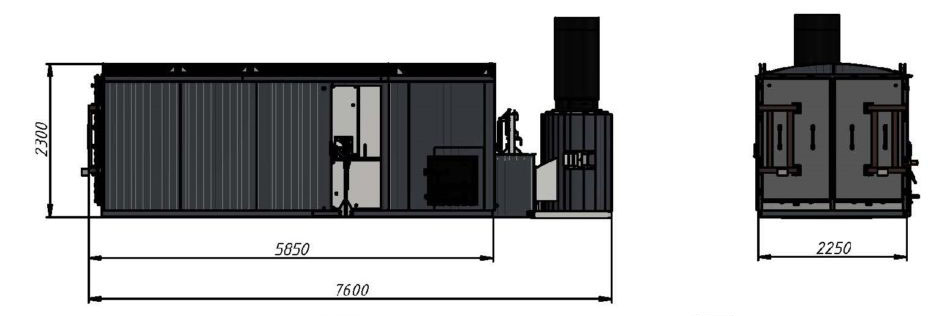

Dimensions

Main elements of furnace

- Firebox

- Сombustion chamber

- Afterburner

- Connecting flue with gate (сombustion chamber – afterburner)

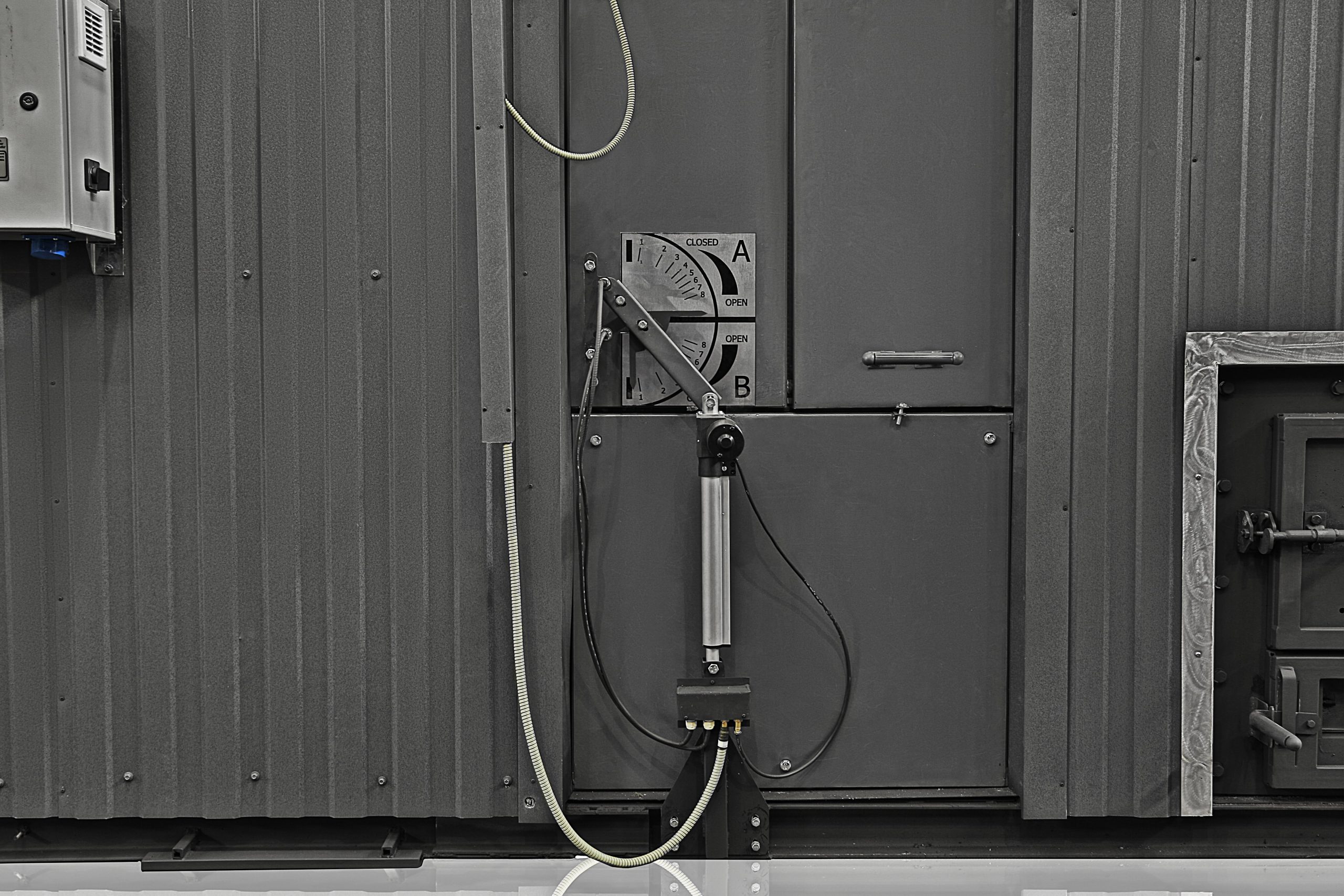

- Drying / pyrolysis chambers A & B

- Operating chamber

- Dampers of chambers A and B

- Gas collectors of chambers A / B

- Gates valves of pyrolysis gas for chambers A / B (butterfly valves)

- Gates valves of steam for chambers A / B

- The heat channels for chamber A / B

- Trolley rails

- Trolley in chamber

Performance of furnace

THE MONTHLY PRODUCTIVITY OF CHARCOAL in TONS, depending on the moisture content of the raw material

| Name and indicators of raw materials | Moisture, % | Output (tons/month) |

| Freshly sawn wood | 55 | 15-20 |

| Pre-dried wood | 25 | 25-35 |

| Pre-dried wood | 15 | 30–45 |

| Fuel briquettes | 10 | 40-50 |

THE YEARLY PRODUCTIVITY OF CHARCOAL in TONS, depending on the moisture content of the raw material in TONS

| Name and indicators of raw materials | Moisture, % | Output (tons/year) |

| Freshly sawn wood | 55 | 165-220 |

| Pre-dried wood | 25 | 275-385 |

| Pre-dried wood | 15 | 330-495 |

| Fuel briquettes | 10 | 440-550 |

* Productivity depends on the density and size of the feedstock

**The highest efficiency of preparing biomass for carbonization is possible only with preliminary drying system using extra heat energy obtained during pyrolysis process.

BASIC PARAMETERS

| Parameters | NOTE | Unit | Qty |

| Maintenance staff for 1-6 furnaces | excluding loading products into trolleys | people | 1-2 |

| Electricity consumption, no more | without raw material preliminary drying system / with system | kWh | 0.1 / 2.2 |

| Consumption of firewood for the furnace, no more* | after the furnace exits “in mode” | m3/day | 0.1 |

| Duty Cycle* | depending on raw material parameters | hour | 4-16 |

| Weight | excluding trolleys and extras. elements | ton | 5 |

| Warranty service | after launch | month | 12 |

*The following indicators affect the efficiency of carbonization furnace

- Humidity of raw materials. Increased humidity significantly reduces efficiency and increases the volume of firewood or other fuel for the firebox. So, when using hardwood just harvested during the movement of sap, the productivity can be reduced by up to 50%.

- The density of the material. For example, poplar having a minimum density requires less energy than a hornbeam, casuarina or iron tree with a maximum density.

- Sizes of pieces of wood or other raw materials.

- The arrangement of raw materials in the trolley: it is recommended to stack large wood at the top, and small wood at the bottom of the trolley

The transportation of a EKKO carbonization furnace set is carried out in trucks (TIR) or with open-top containers 40ft.

INTERESTED IN PURCHASING?